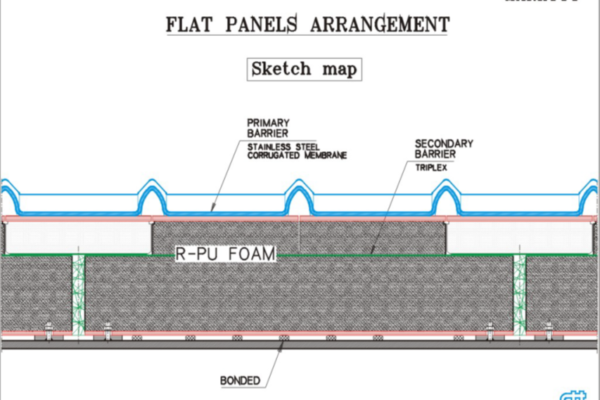

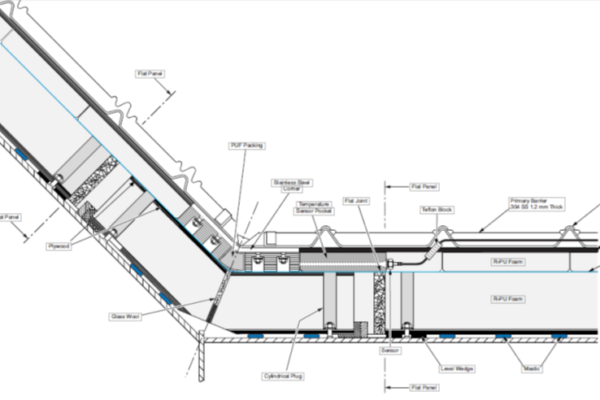

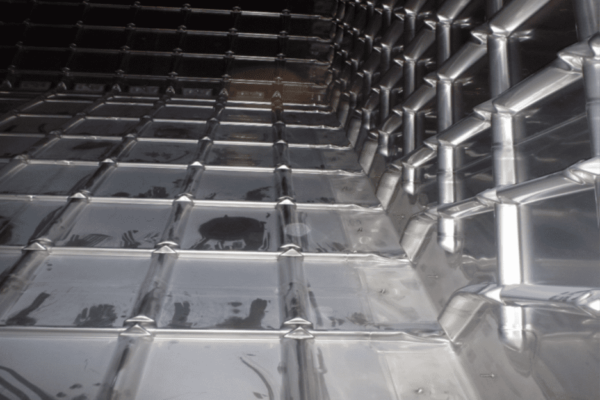

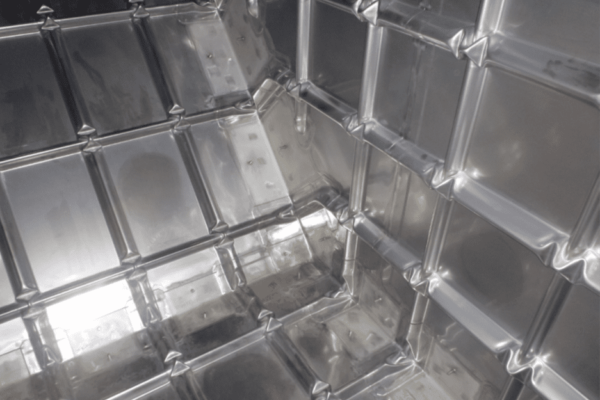

A 929-foot-long LNG carrier recorded abnormal gas communication between IS (insulation space) and IBS (inter Barrier Space) when conducting a secondary Barrier Tightness Test (SBTT) to confirm vacuum decay rates and further investigation was arranged in way of SGS carrying out an acoustic emission test.

A service company was selected by the Owners to carry out the acoustic emission test of the remaining cargo tanks to locate leaks and identify any possible additional repairs and a leak points were detected at the bottom forward port side of tank No.2 on “D” wall during the first acoustic emission test by SGS.

At that time, the bonding failure was common to the vessels built by the same shipyard up to 2008. The shipyard acknowledged the problem of the triplex bonding and made some modification to their manufacturing process and bonding procedures.

However, the remedy was not applied to existing vessels built before 2008 and many vessels, as this, experienced the above problem.

The repairs cost was about USD 800,000.